Subsea

We’ll stop you drowning under the weight of subsea test requirements.

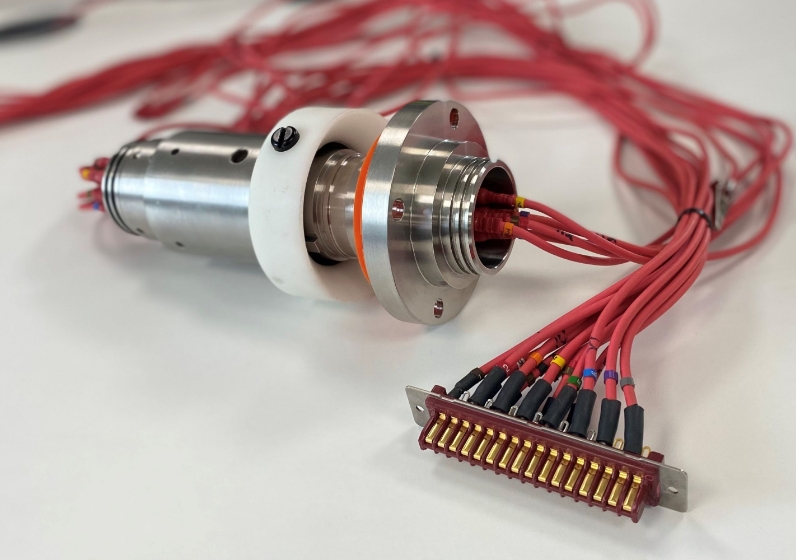

Electrical interconnect systems often carry high current and high voltage, and deployed to extreme depths where failure of such components is catastrophic and has massive financial consequences.

These interconnect systems experience extreme pressure and temperature cycling during power on and power off. Our systems can work independently to test continuity and insulation, or work in conjunction with pressure vessels and climate chambers. Our advanced API allows full control from third party software, or our software can be deployed to control third party devices.

Our products are compliant to SEPS and NORSOK standards. We’ve supplied specialist test equipment to some of the world’s leading interconnect manufacturers including TE Seacon and ThyssenKrupp.

Did you know?

The first transcontinental cable was laid in 1858 and ran from Ireland to Newfoundland.

Today, 99% of all internet traffic travels through the 1.1million km cable network.

Main Subsea Applications

Interconnects and connectors

Tree systems

Umbilical cables

HV cable testing

Recommended Products

Automeg ®

Portable Automeg ®

RTS ®

Download THE Brochure

Some of our subsea customers